The upgrading of industrial digital intelligent manufacturing brings new opportunities and unlimited development potential for the future development of enterprises. In particular, traditional manufacturing enterprises upgrade the production line and connect machine vision systems in each production link, which can effectively improve the efficiency of the production line. Through intelligent transformation, the automation, informatization and digitalization of the production process can be realized, thereby improving the competitiveness of enterprises.

From the perspective of application scenarios, it is currently mainly concentrated in many industries such as new energy vehicle manufacturing, medical pharmaceuticals, logistics and warehousing, and financial services. According to the application technology field of machine vision, it can be divided into four important components: code reading and recognition, product visual inspection, machine vision measurement, and machine vision positioning. With the development of artificial intelligence technology, it will gradually be extended to other application industries in the future.

Code reading and recognition

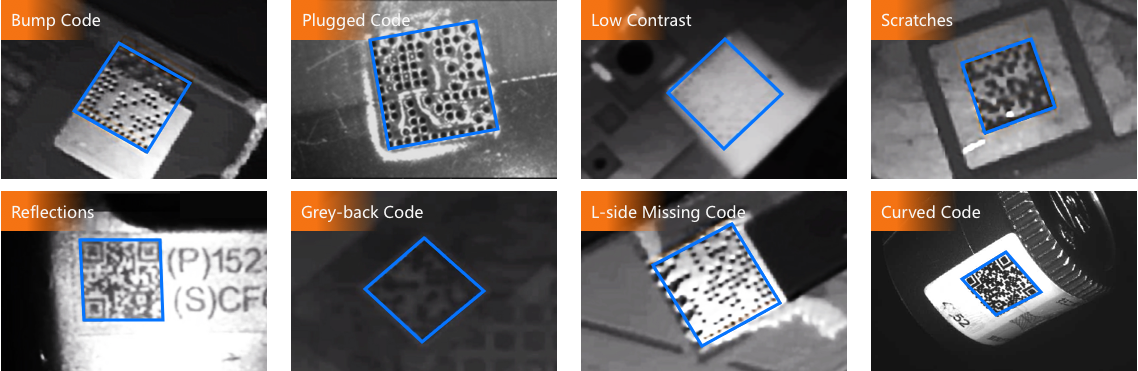

Barcode reading in complex environments

In the high-speed production line, the barcode recognition that still relies on manual manipulation by humans will affect the production efficiency of the production line. Affected by many uncertain factors such as the complex environment on the production line, the material of barcode printing, and printing quality, it is difficult to guarantee the accuracy of recognition.

Use machine vision solutions to quickly collect production line codes, use AI intelligent algorithms to realize image collection, conduct independent learning and analysis of barcodes under different working conditions, and realize high-speed barcode recognition, OCR character reading, data reading statistics, etc. .

Product Visual Inspection

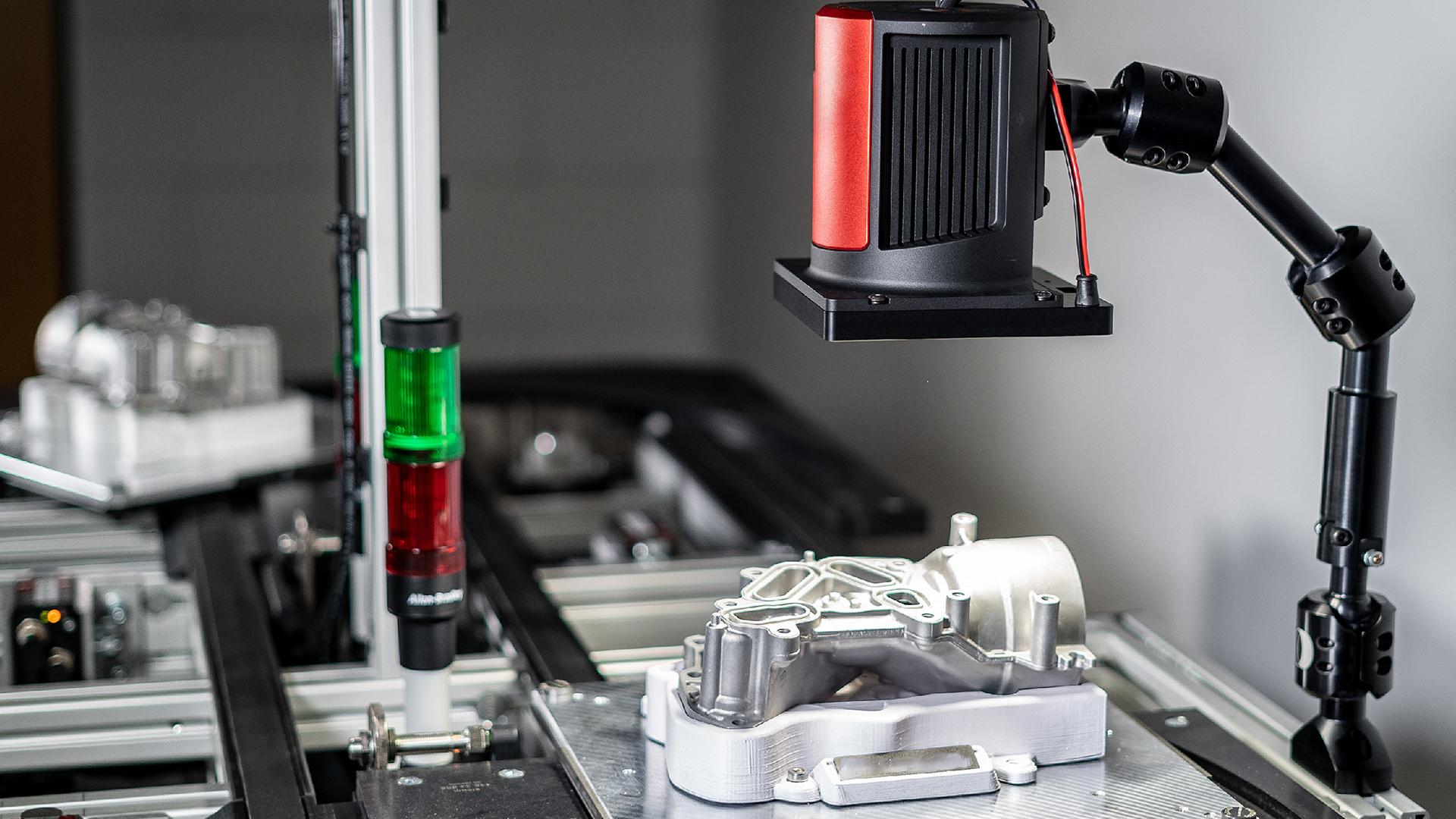

Product Defect Detection

In the automated production process, product quality inspection covers: product surface quality inspection, product installation inspection, product display defect inspection and other links. The addition of the machine vision inspection system can provide customers with better services, further improve product quality and production efficiency, improve the flexibility and automation level of the production line, and reduce defects caused by manual inspection.

Machine Vision Measurement

High precision measurement accuracy

With the development of electronic products and high-precision processing industries. Measuring with naked eyes and traditional measuring tools alone can no longer meet the current needs. More precise measuring instruments must be used. Machine vision measurement can effectively measure the processed products in all directions, and detect parameters such as radius, width, and length. The measurement error is controlled within a very small range, and the machining accuracy is greatly improved.

Machine Vision Positioning

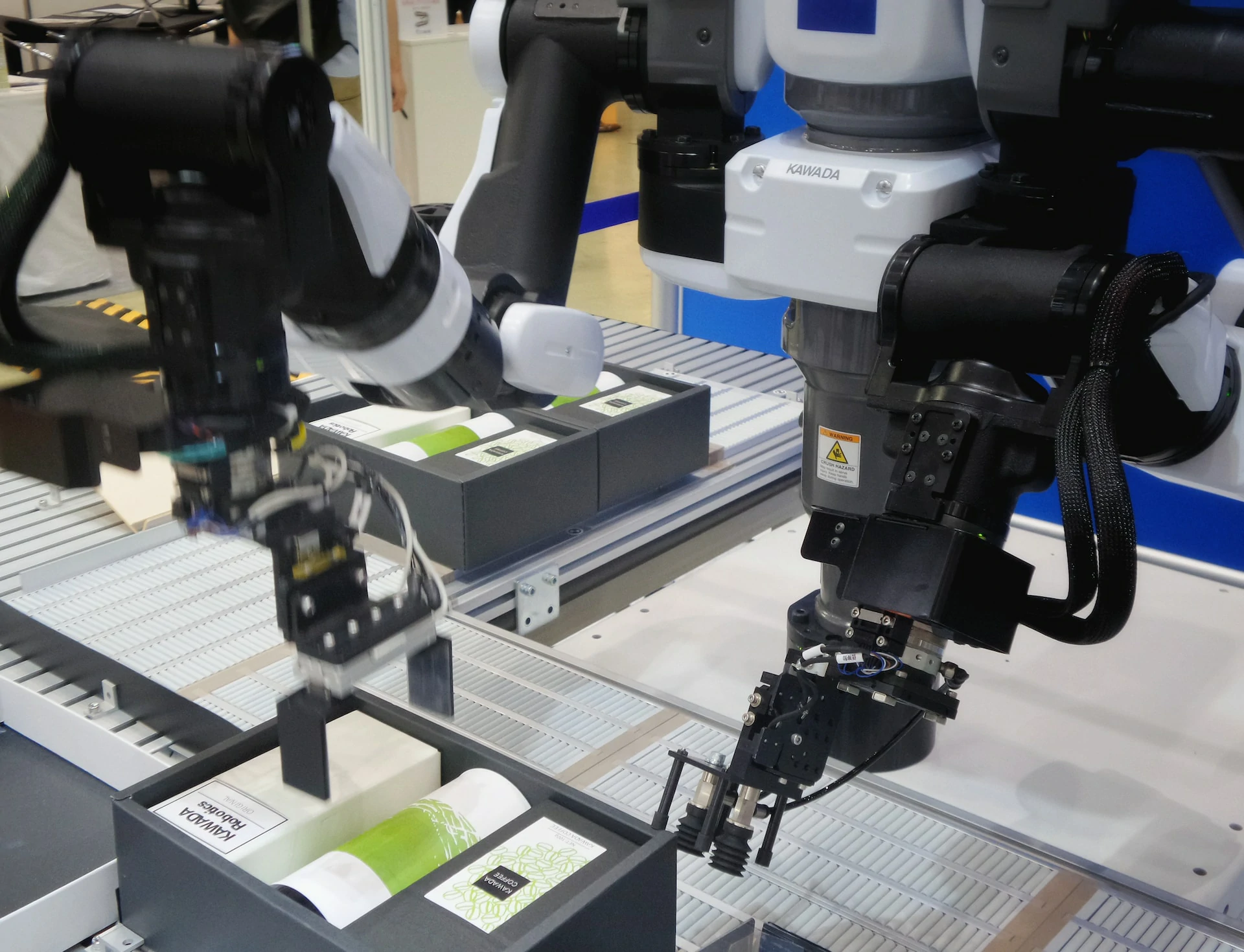

Accurate positioning improves efficiency

The vigorous development of unmanned factories has benefited from the production line robot-assisted production. In the past, the manual positioning method was prone to various deviations and fluctuations, requiring manual intervention and adjustment in time, which seriously affected the production speed of the production line. After the introduction of machine vision positioning technology, the position of products or parts can be automatically judged through machine vision equipment. Even if there is a deviation, it can be corrected through the self-learning model, and the relevant data is simultaneously transmitted to the robot for real-time operation.

Smart Manufacturing Helps China's Production Industry Improve Efficiency

The four major application areas of machine vision are introduced, which play an important role in different processes of the production line. With the wide application of intelligent manufacturing in various industries, it will help the traditional manufacturing industry to achieve leapfrog development. The machining accuracy with smaller error, more flexible production process, and more efficient management mode will enhance the competitiveness of enterprises in the industry and empower the consolidation of industrial advantages.

Please select your service type and leave your information so that we can provide the appropriate service. Xincode looks forward to working with you.