The intelligent upgrade of industries is bringing unprecedented challenges and opportunities to traditional home appliance manufacturers. Machine vision, as a key technology driving smart manufacturing across various sectors, is continuously powering the digital transformation of traditional industries. It helps home appliance companies significantly boost production efficiency, improve product quality, and reduce daily operating costs.

Automated Quality Inspection

Using high-precision cameras and smart algorithms, machine vision can detect various defects in products in real-time during the production process, preventing issues such as scratches, color inconsistencies, and abnormal shapes. The integration of machine vision also enables 24/7 uninterrupted operation, reducing errors and delays caused by manual inspection, ensuring that every product meets the factory's quality standards. This technology offers reliable support for the creation of "dark factories" in the home appliance industry.

Accurate and Smart Product Assembly

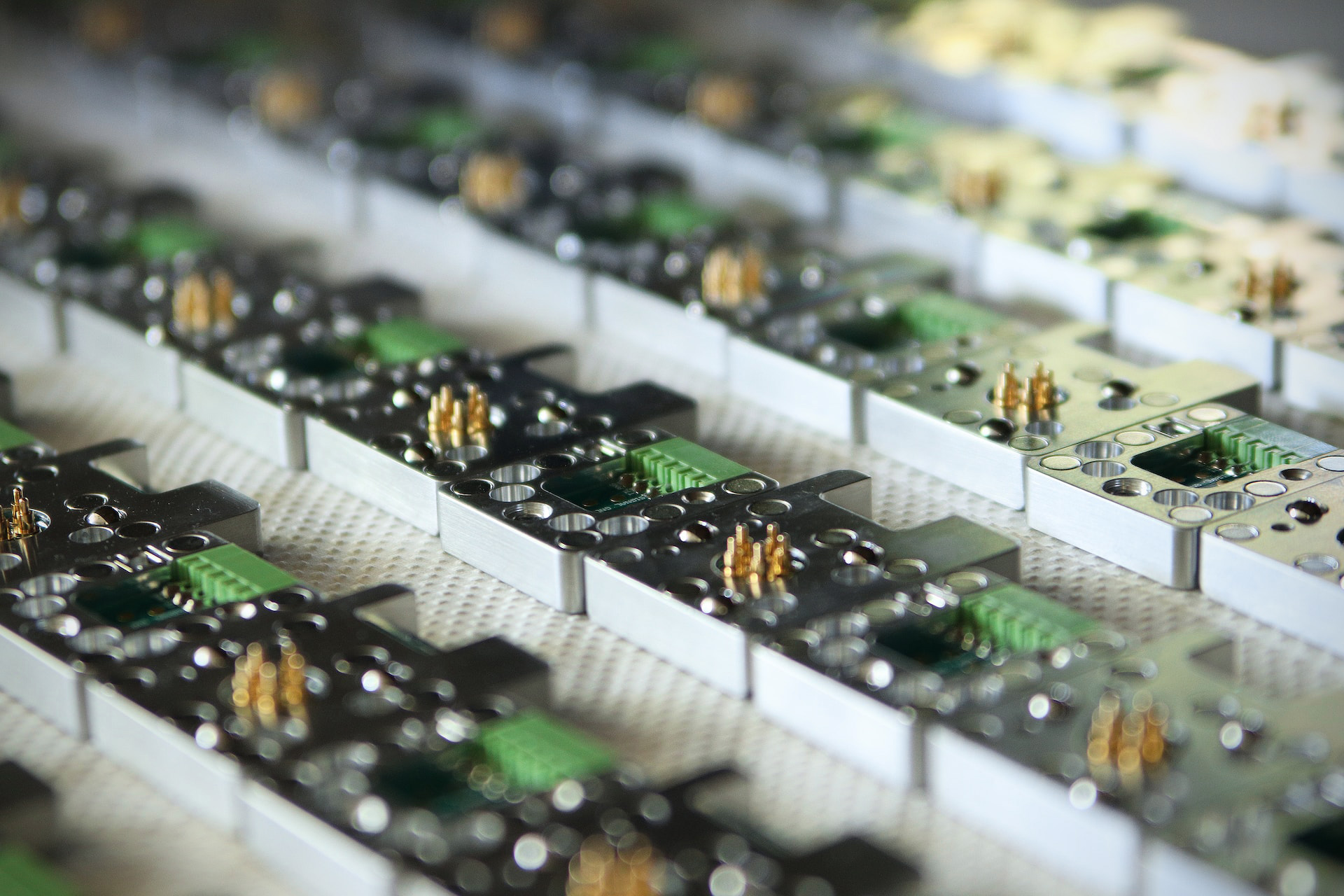

In the production of home appliances, the precision of component assembly directly affects the performance and lifespan of the products. Machine vision equipment collects data on various parts and compares it with the design specifications. Through 3D imaging and deep learning algorithms, it accurately identifies and positions different components, guiding robotic arms for precise assembly. This reduces labor costs and enhances the consistency and reliability of the products.

Real-Time Production Monitoring

By deploying machine vision systems on production lines, companies can achieve comprehensive real-time monitoring of the production process. These systems can automatically detect anomalies, such as equipment malfunctions or material shortages, and promptly issue alerts. This enhances production stability and provides reliable data to support the optimization of production processes.

Data-Driven Production Processes

The vast amounts of production data generated by machine vision systems can help companies optimize their production processes. By deeply analyzing this data and building visual models, companies can identify key areas for improving process efficiency. Additionally, this data lays a solid foundation for future automated decision-making.

Smart Warehousing and Logistics Management

Machine vision also plays a crucial role in warehousing and logistics management. By automatically identifying and classifying materials and finished products in the warehouse, it enables smart inventory management and fast logistics scheduling. This improves warehousing efficiency, reduces material misplacement and inventory buildup, and achieves comprehensive optimization of the company’s supply chain management.

Conclusion

In traditional home appliance manufacturing, digital transformation has become an inevitable choice for enhancing competitiveness. With its powerful data processing and analysis capabilities, machine vision is gradually becoming a key driver of business transformation. As global manufacturing accelerates its shift towards intelligence and digitalization, companies should actively embrace this technological change, leveraging the advantages of machine vision to enhance their market competitiveness and inject new vitality into their sustainable development.

Please select your service type and leave your information so that we can provide the appropriate service. Xincode looks forward to working with you.