Emergence of New Energy Vehicle Brands

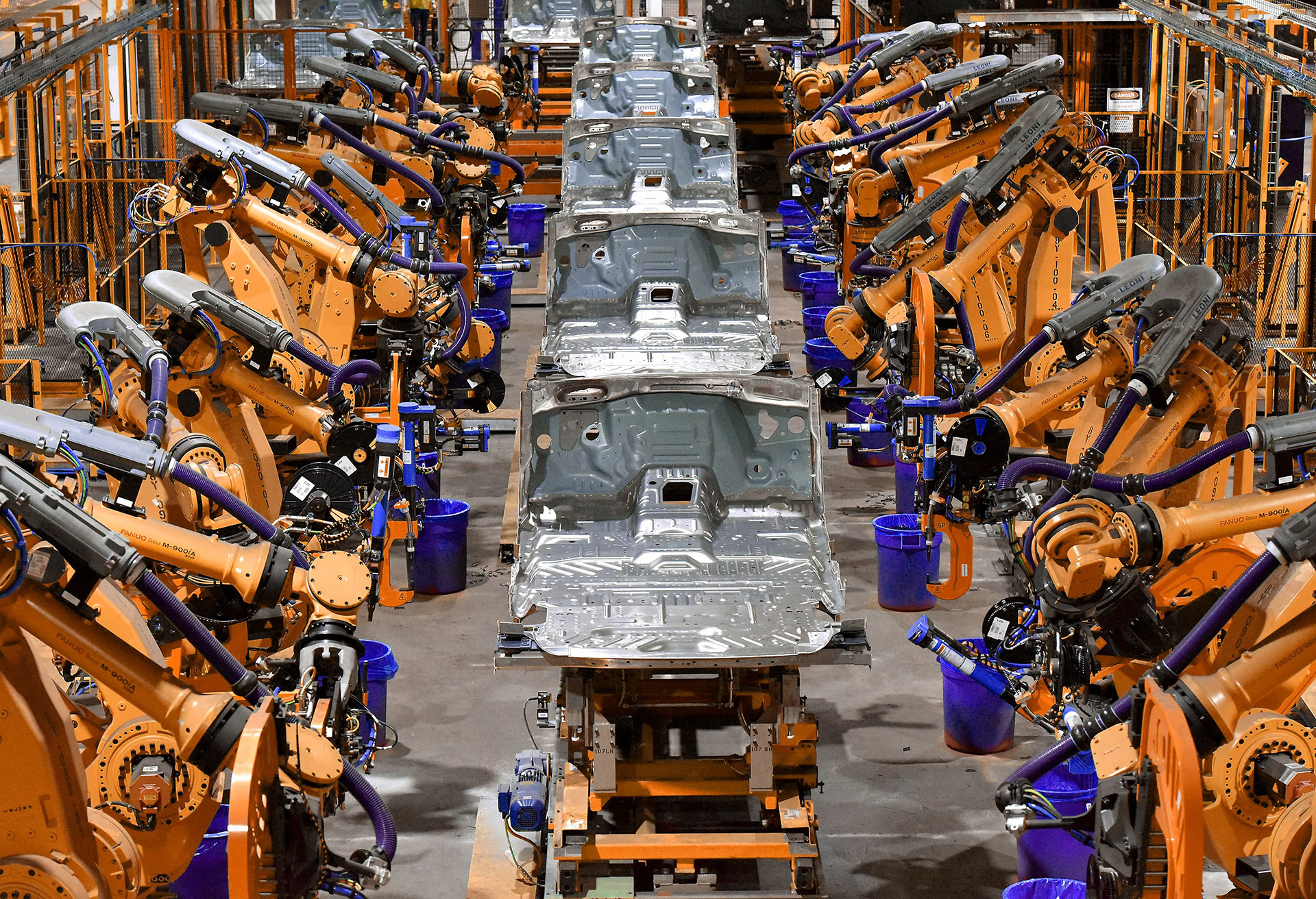

In recent years, the rise of new energy vehicle (NEV) brands has been transforming our daily transportation with smart, eco-friendly, and convenient options. The automotive manufacturing sector is also quietly undergoing changes with the adoption of intelligent manufacturing models. Today, we will delve into how machine vision and barcode recognition devices are helping the NEV manufacturing industry move towards a smarter and more efficient future.

Quality Inspection and Defect Identification

Quality control is a crucial aspect of NEV manufacturing. By using machine vision inspection equipment, the production quality of components and semi-finished products can be comprehensively inspected, detecting minute defects that are hard to spot with the naked eye. During the vehicle painting process, vision systems can check for uniformity and color differences in the coating. In welding processes, they can assess the quality and position of weld points, ensuring they meet the factory quality standards.

Parts Traceability and Management

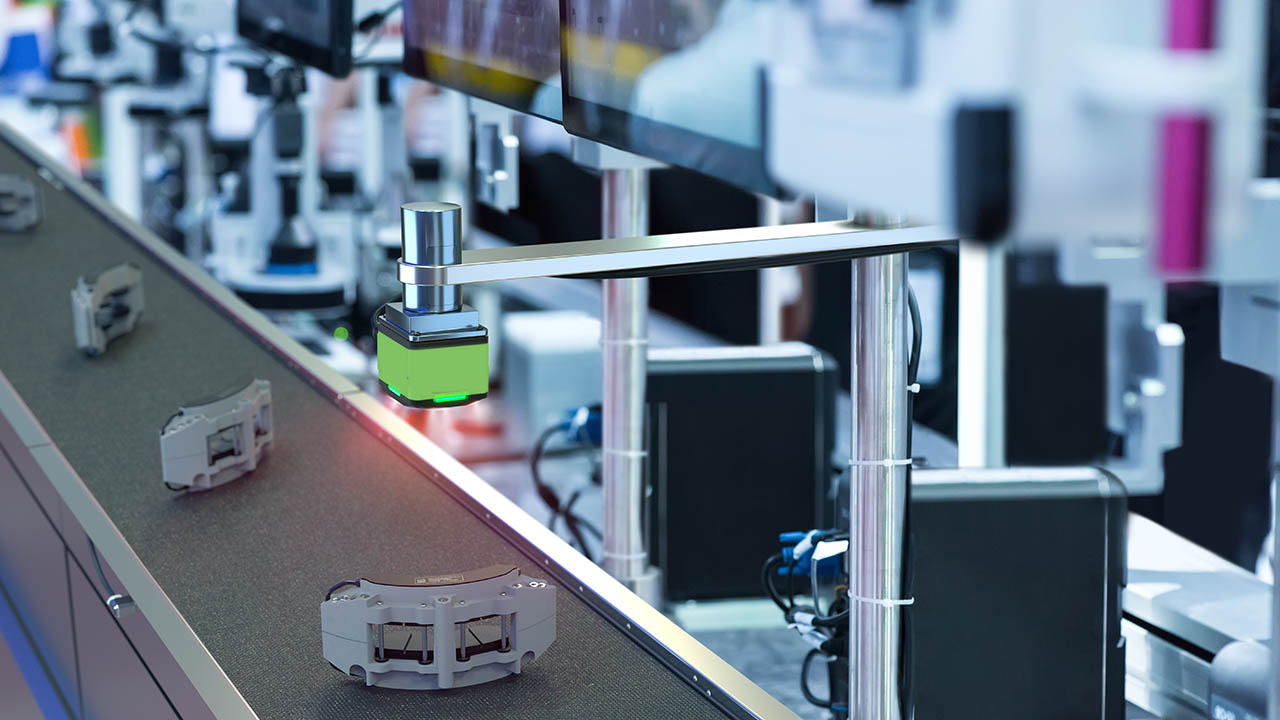

In the NEV manufacturing process, there is a wide variety of parts. To ensure the quality and traceability of these parts, each component must be barcoded before entering the assembly line. By scanning the barcode, relevant production information of the parts can be retrieved, enhancing assembly line efficiency and preventing the omission of parts during manual assembly.

Recommend Product

Inventory Management and Logistics Tracking

In logistics and inventory management, the widespread application of barcode recognition technology plays a significant role. During the logistics transportation process, barcode recognition technology allows both vehicle owners and automotive brand 4S stores to track the real-time status of the transport vehicles. This digitizes the entire logistics chain, making it transparent to all target groups involved.

Recommend Product

After-sales Service and Maintenance Management

Barcode recognition technology is also crucial in after-sales service and maintenance management. When NEVs leave the factory, they are assigned a unique chassis number and a corresponding QR code for future information identification and entry. This barcode contains all the information about the vehicle. After-sales service personnel can scan the barcode to obtain the vehicle's maintenance records and repair history, providing more precise and efficient repair services.

Recommend Product

Conclusion

The extensive application of machine vision and barcode recognition technology in the NEV manufacturing industry not only improves production efficiency and product quality but also significantly reduces costs and enhances customer satisfaction. The widespread use of these technologies signifies that the NEV industry is moving towards a more intelligent and refined direction, bringing more surprises and convenience to our green travel.

Please select your service type and leave your information so that we can provide the appropriate service. Xincode looks forward to working with you.